Plant Machinery and Work Inspection checks

Effortlessly manage plant Machinery and Work inspection checks with Vehocheck.

Eliminate unwieldy and time-consuming paper-based check systems, improve safety and compliance records of plant machinery and work equipment.

Similar to DVSA daily walkaround checks for commercial vehicles, Health and Safety Executive (HSE) plant machinery and work equipment inspections checks are a set of checks that can be carried out on a daily, weekly, monthly or quarterly basis.

Using Vehocheck helps construction companies with compliance and reporting against safety regulations, including PUWER (Provision and Use of Work Equipment Regulations 1998) and LOLER (Lifting Operations and Lifting Equipment Regulations) as well as DVSA guidelines for the road-going plant.

A comprehensive defect reporting and management process means that you can be proactive about discovering, reporting and rectifying vehicle and equipment defects. This gives you a clear digital audit trail for compliance purposes, as well as ensuring that defects are quickly reported and promptly rectified

"The Vehocheck system is a positive step to digitise some of our business processes, the system is easy to use for everyone in the business and has some great features to ensure compliance in the business"

Chris Cotton Head of UK Operations, HIS

PUWER specifically outlines that plant machinery and work equipment should be:

- Suitable for its intended use

- Well maintained, safe for use and regularly inspected

- Only used by people with adequate information, instruction, and training

- Covered by appropriate health and safety measures

- Used in conjunction with other specific safety requirements where they also apply.

In addition to the legal requirements around health and safety responsibilities, conducting thorough examinations, regular checks and maintaining work equipment and plant machinery is good business practice.

A comprehensive defect reporting and management process means that you can be proactive about discovering, reporting and rectifying vehicle and equipment defects. This gives you a clear digital audit trail for compliance purposes, as well as ensuring that defects are quickly reported and promptly rectified

Using Vehocheck to manage plant machinery and work equipment inspections and maintenance, construction companies and operators can make the defect and maintenance process more efficient, by reducing the time and resources spent recording defects, rectification and storing paper-based inspections.

Designed to not only fully streamline the inspection process and remove the need for manual paper trails, but Vehocheck also gives operators the facility to submit and view plant machinery documentation, certifications and much more.

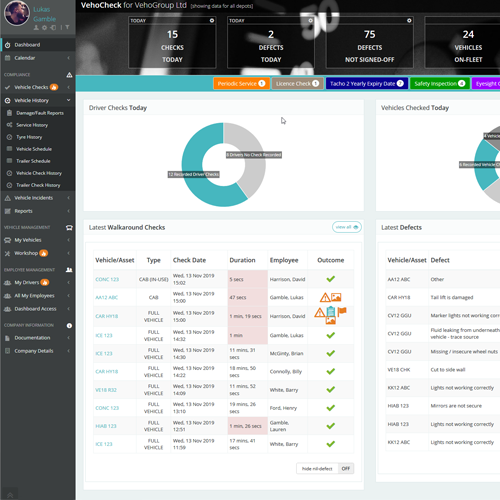

All reports submitted instantly alert the plant/asset manager and or SHE manager in real-time and can be audited and managed from within the Vehocheck dashboard giving you complete control and visibility of all your plant and assets

With Vehocheck, you can be confident that your inspection and rectification process is robust and complies with the DVSA, HSE, PUWER and LOLER safety and maintenance guides.

"After the trial period we have engaged several hundred staff on the journey & growing stronger to enable better compliance, visibility of the fleet & engagement of the staff"

David Keir Senior Business Development Manager HIS

Ensure DVSA, HSE compliance and manage your fleet and assets with Vehocheck

Defect and Incident App

- Compliant HSE, PUWER and LOLER checks

- Quick and easy to use

- Intuitive Guided Inspections

- Defect Reporting and Accident/Incident reporting

- Record asset "Safe-to-Use"

- Real-time reporting

- Document sharing

Plant and Asset Management Visibility

- Defect management

- Compliance and safety reporting

- KPIs and cost analysis

- Monitor plant and asset usage

- Maintenance Scheduling

- Full document storage and data integration

Workshop Maintenance and Management

- Monitor plant and asset non-usage

- Manage key inspections, maintenance and servicing dates

- Job card creation and management

- Store and view all PUWER and LOLER examinations

- Repair cost analysis

- Calendar view (calendarised) scheduling

- Asset service history.